After ruining my rebuilt engine I started looking out for a replacement piston. This proved pretty difficult because early 16vs had a different combustion chamber shape. In the end I found a later style B202 taken from a 9000 with 87k miles for only £120 delivered, which is great!

The 9000 engine isn’t a straight fit in the 900, all of the ancillaries are mounted differently due to the fact the engine is transverse with an end-on gearbox in the 9000. Basically the block end plates, manifolds, oil pick up pipe and all ancillaries must be swapped over but the bare block, head and internals are identical.

Thanks to lockdown it was a while before it could be delivered, but on a freezing day in February it arrived and I was stripping and cleaning it. It had been stored with the cam cover off so at the very least I was planning to replace all of the gaskets and thoroughly clean out the head.

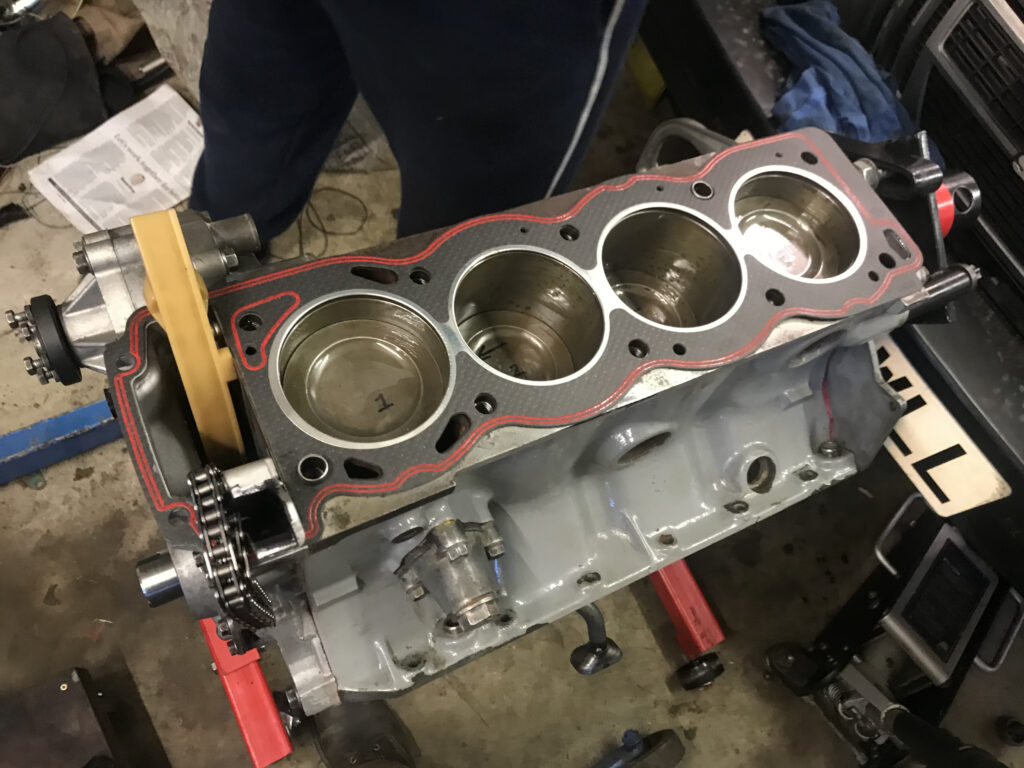

Unfortunately, once I removed the head I found that the bores were bizarrely worn. I’ve had the head off these engines with 200k+ miles and still been able to see the crosshatching in the bores, but for some reason these bores were worn smooth. I was told it was running great when removed, but I didn’t want to have gone to all of this effort for a worn out engine, so it was full rebuild time. Again.

Both blocks and cranks were taken to the machine shop for them to choose whichever they felt was the easiest to save – scored from the cracked piston or generally worn.

In the end, happily the machine shop felt that the original block would be fine with another honing and no need for oversized pistons, while the new engine’s crank was the better starting point for polishing. I also had them skim the new engine’s head (which must be paired with the pistons due to the different combustion chamber shape – hence why I couldn’t keep the old head) after I cleaned and lapped in the valves.

So now it was time to build the new engine’s internals into my old block. Nothing much to note about that, it’s becoming pretty frustratingly familiar by now.

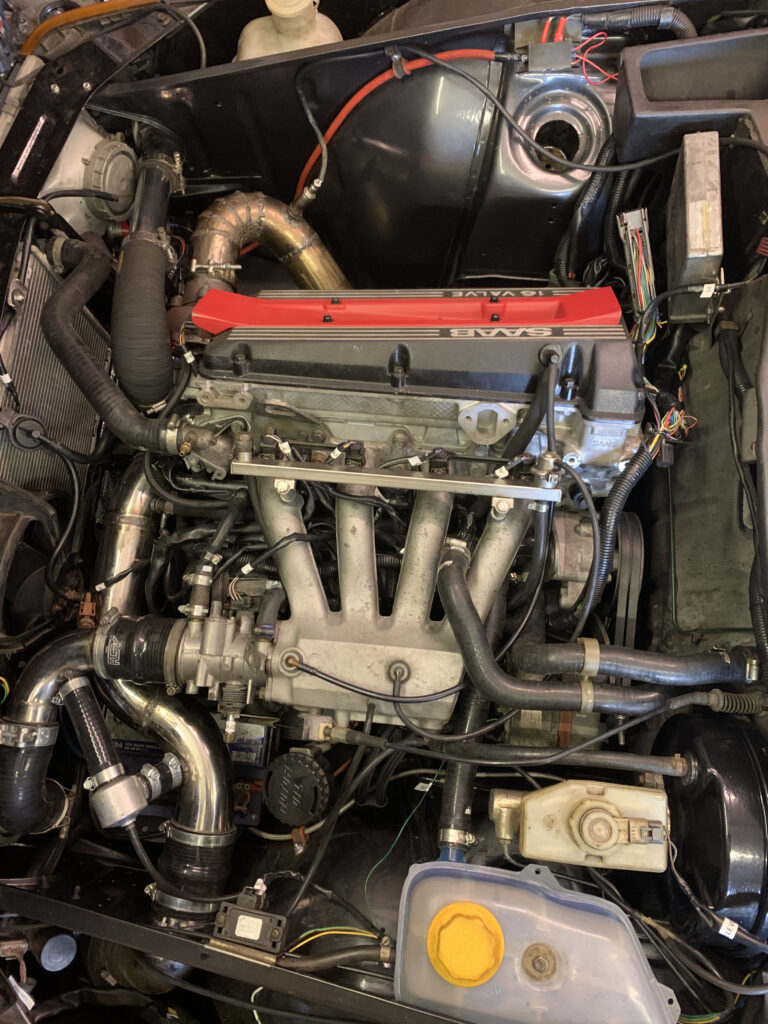

Once the engine it was in, I ruined the slave cylinder again at first startup (I’m getting good at this trick) by forgetting to remove the clutch spacers, which meant the piston over extended, popped out and mashed up it’s seal. Not hard at all to replace but pretty frustrating.

Other than that setback, it started up first time with good oil pressure so I’m running it in on base boost before I can start to tune. There’s a list of snags to sort but nothing too major.