No surprise, barely a week after I got Helga back on the road was there a puddle on the floor by her left front wheel – the caliper’s seals had failed. Helga’s got a really rare brake setup – front handbrake with vented discs. I think these were only offered on turbo cars for one year before the switch to rear handbrake. So, with no chance of finding replacements, a rebuild was in order.

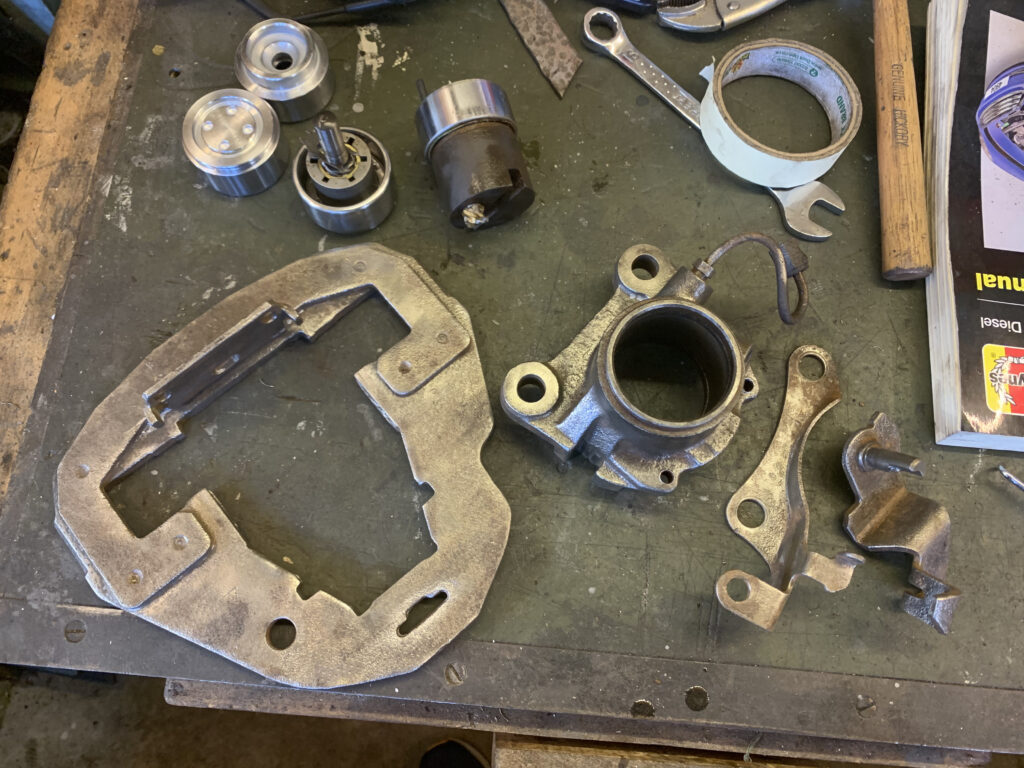

These calipers work in a really weird way, with two opposing pistons on the rear side of the disk floating in a flat yoke.

The main parts came apart in a pretty straight forward manner, but as you can see the replacement pistons don’t have the extra gubbins for the handbrake mechanism attached so I had to figure out how to swap them over. The rearmost piston wasn’t too hard, because it pried apart with a paper gasket between the pieces but it was very hard to get the screw mechanism out of the inner piston without damaging it. To hold it in, I sharpened the end of a bunch and gave it some wallops all the way round to deform the edge and retain the lip of the inner mechanism. Hard to explain, easy to see in the photo.

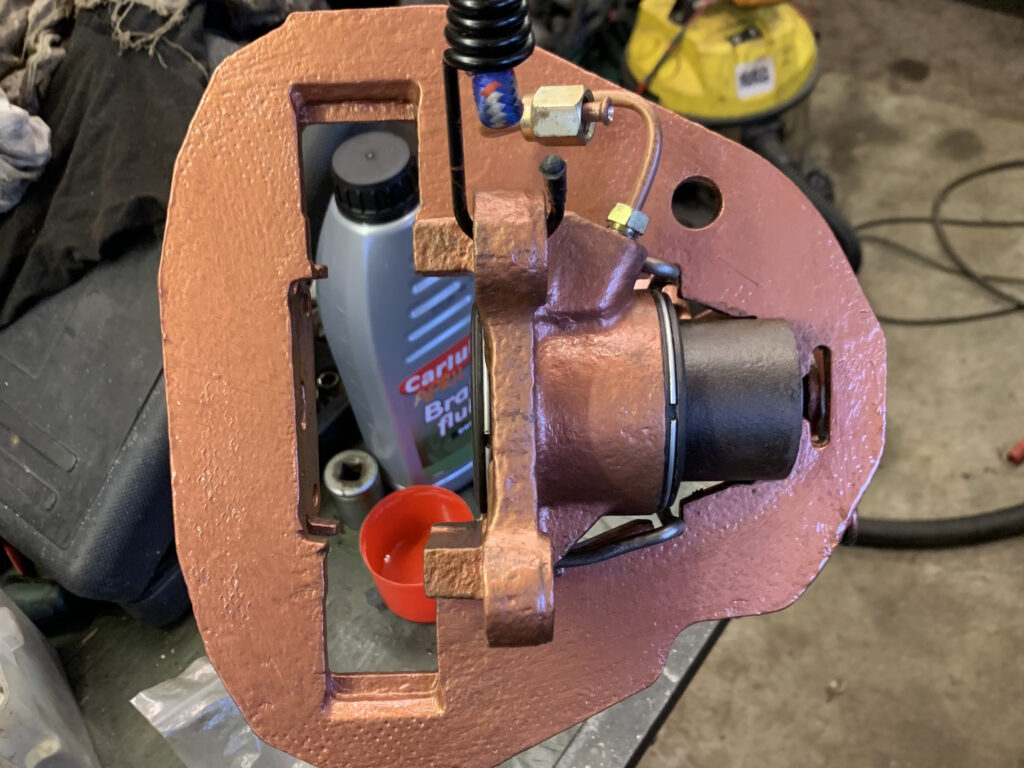

Over time the yoke that the caliper slides on wears, allowing the caliper to rock back slightly when you reverse. To fix this, I ran a bead of weld on the sliding edge and filed it flat until the caliper slid easily without wobble.

After that, it was just a case of painting with high-temp paint, reassembling with new seals and making up a new hard line.

I was trying to get the car back together in time to go camping, but surprise surprise the 90 degree AN fittings I’d used on the turbo oil feed decided to spring a leak the night before. Not at the connection but the swivel portion which is odd. Even more annoyingly the line is now a tiny bit too short so I’ve got to make up a whole new one. Trying the braided PTFE hose this time instead of rubber core. Hopefully soon I’ll have done enough miles to drop the running in oil and can start mapping her.